ATOS Core

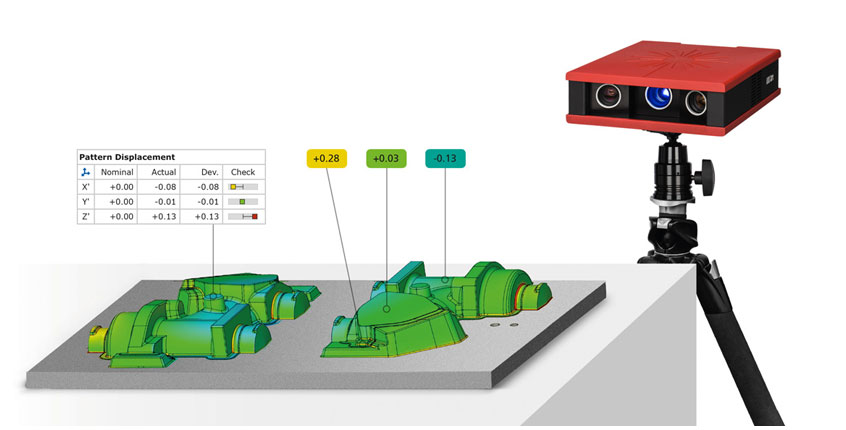

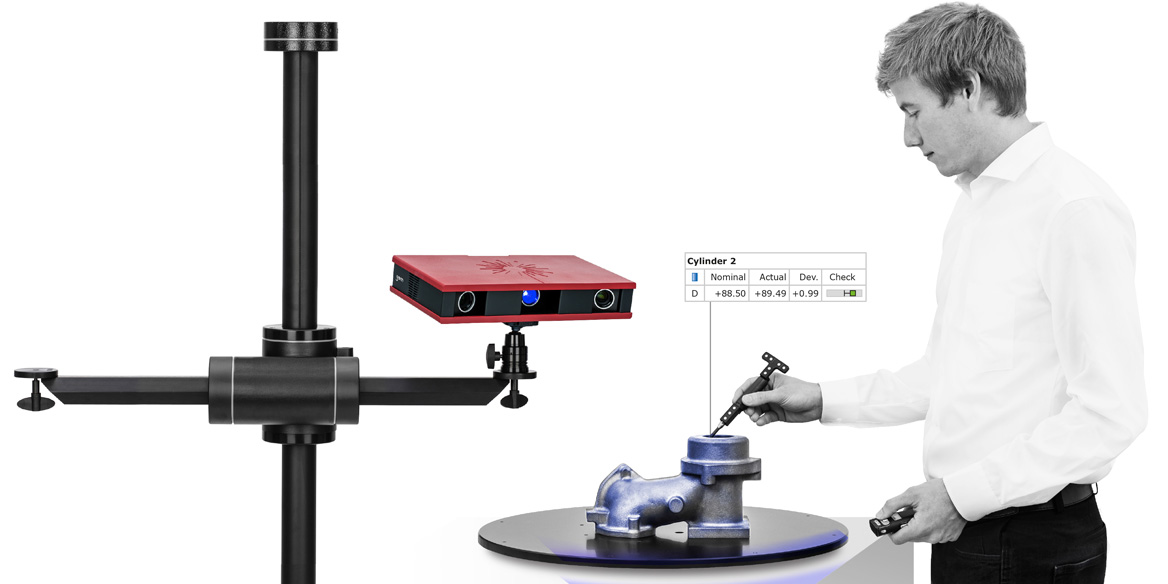

ATOS Core is the specialist for small components

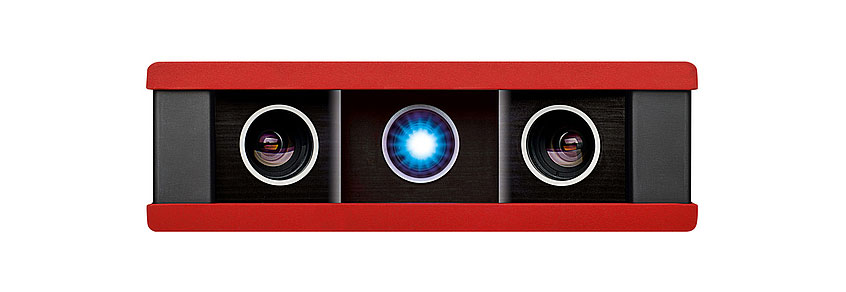

ATOS Core Technology

Triple Scan Principle

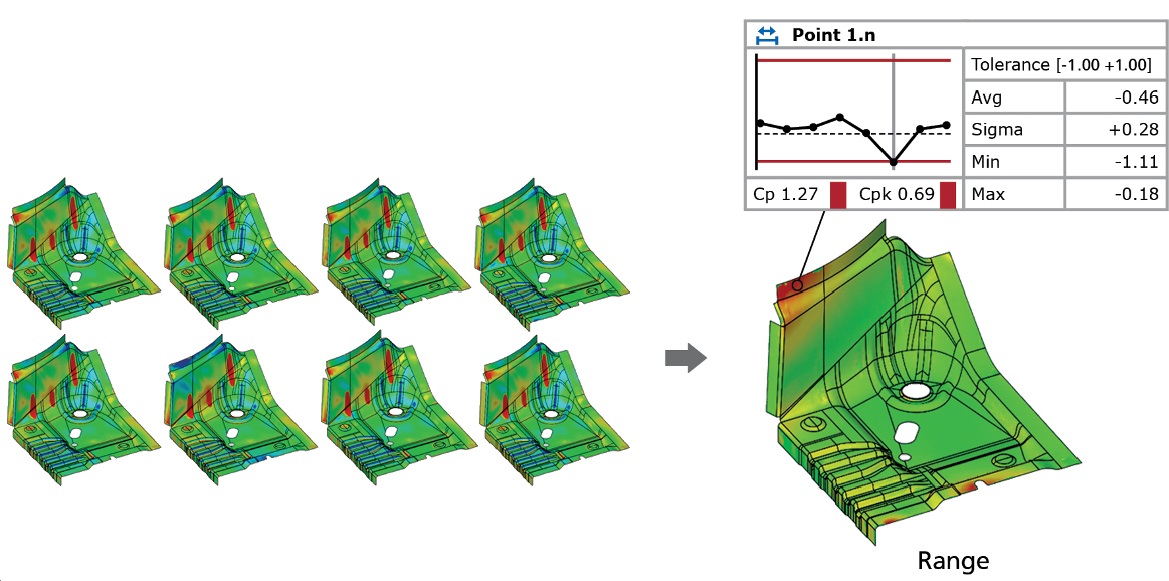

Self-monitoring system

The ATOS Core is a self-monitoring system

Benefits

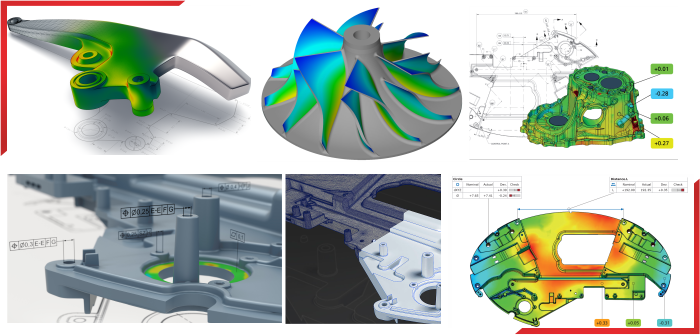

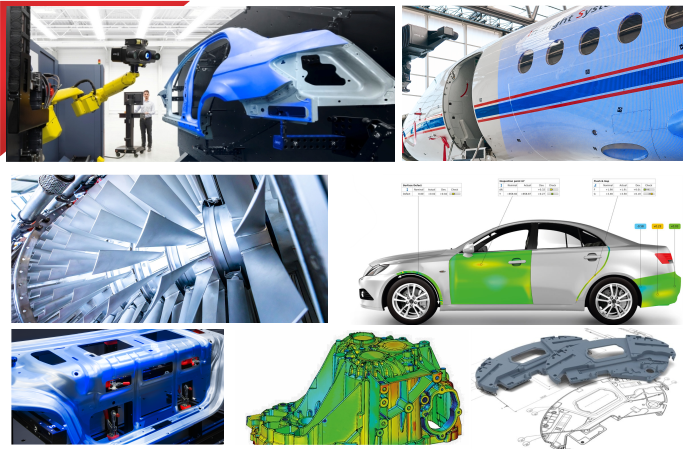

Applications

ATOS Core is used in the manufacturing process of the automotive, aerospace, consumer goods and medical industries as well as for the research institutes and universities.

Sheet Metal

Casting

Plastics

Additive Manufacturing

© 2021. APM Technologies

Copyright © 2021. All rights reserved