Customer login

Not registered yet?

Register now! It is easy and done in 1 minute and gives you access to special discounts and much more!

RPT

- Home

- RPT

RPT

Additive manufacturing - The new age Wonder

"Additive manufacturing is the use of specialized equipment to create a physical product using 3-dimensional computer aided design fabricated using 3 dimensional printers.

These range from basic inaccurate desktop 3d-printers to highly accurate 3d-printers costing a fortune. 3D Systems MJP 3600 Max Resin printer used by us is capable of producing part detail with an accuracy of up-to 16 microns (1600 DPI).

Process

The 3D Systems ProJet MJP 3600 Max 3D printer uses the MultiJet 3D printing technology. It prints thin layers of UV-curable liquid resin (photosensitive) onto a platform, using wax to create supports that brace the part during production. UV lamps cure each layer, and the build platform lowers for the next layer. This process continues layer by layer until the part is complete.

In today’world, to cater to a highly competitive market, manufacturers can benefit by adopting to the technology of the future - making production time less and hence saving cost while meeting new release schedules in the product development cycle”

Finished Product

The part attained after casting has a smooth finish and does not require extensive manual finishing which in turn reduces the time and the cost incurred, leaving the designer free to spend the saved time& money to procure better materials and invest more in the manufacturing process.

Phase changes process

Possible due to proprietary thermally-controlled material for superior print definition. As each heated droplet of material is jetted, it immediately cools and holds its shape as it land on the part or support surface.

Benefit of Multijet Printing

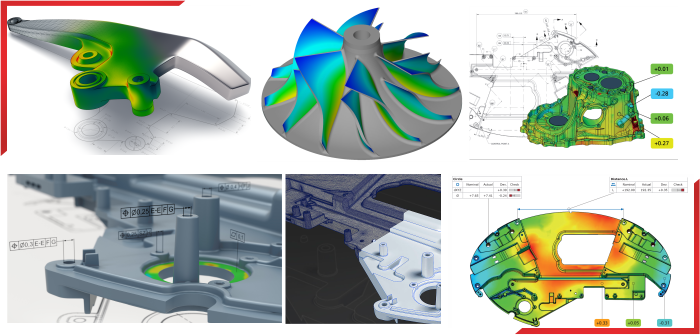

The Projet MJP 2500 series, 3600 series and 5500X employ Multijet Printing technology to produce the highest fidelity, truest-to-CAD parts of any jetting 3D printing process.

Services offered

3D Printing / Caming from your CAD files- APM offers 3D printing from you CAD files an high resolution hmachine MJP-3600 Max to offer you unmatched quality of output.

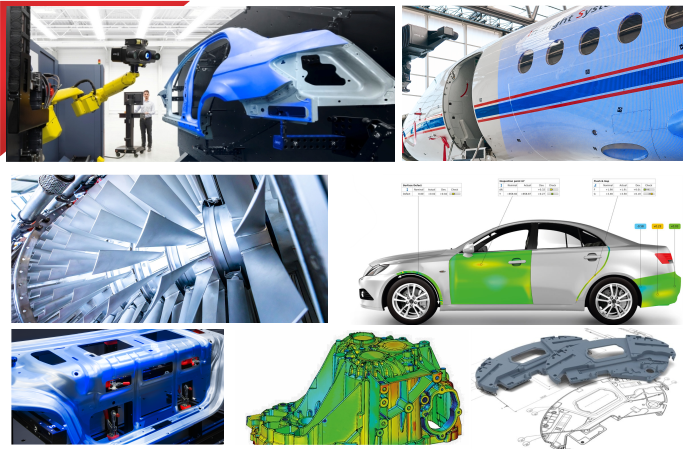

3D printing from existing parts by 3D Scanning - APM has the capability to generate STL CAD file from your existing parts or patterns which can their be printed for replication. Also sizing can be easily done or scanned parts to prints patterns in various size.

3D Scanning of existing parts - APM can scan & generate dedicated STL file from existing pattern which can be used for

Advantage you get with APM

Experienced 3D-Profesionals - APM brings an expertise of over 20 years of excellence in 3D technology using top of the line 3D Scanners & 3D Printers.

Security and Confidentiality of Design - APM guarantees complete security & confidentiality of your design by using an elaborate electronic security system. Many industrial design house and automotive design companies and OEMs have extended their faith & trust in APM since 1999.

Accelerate time to market- Bring product to market faster. Validate design, test performance and manufactur-

ability and fix design flows early, this ensuring the part has thoroughly tested before committing to the cost of casting.

Reduce cost - Accurate prototype save cost by using the exact dimension of the CAD , making sure no extra precious metal is being used during casting due to in-accurate watering consistency. This reduces the need or rework. APM is also equipped to help the customer make changes to a part virtually via 3D-Scanning.

No Support marks on the finished product – Use of wax supports ensures no support marks are present on the printed part hence reducing the need for greater post processing before and after casting.

Single source for 3D printing & 3D Scanning - APM is equipped with the latest high end 3D-Scanners & 3D Printers

to are with service for 3D Scanning & 3D printing.

Pickup and delivery facility to you door step, all the expertises & benefits of working with APM.

Full check of every individual jet at each layer helps reduce the slightest of errors and hence attain perfection and

generate the most TRUE-TO-CAD part of any jetting 3D printer.

© 2020. APM Technologies

Copyright © 2020. All rights reserved