Sheet Metal Forming

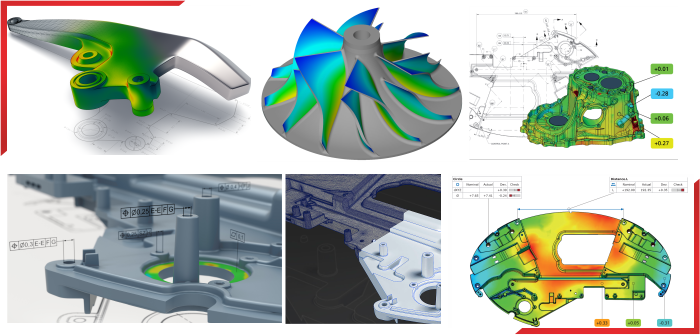

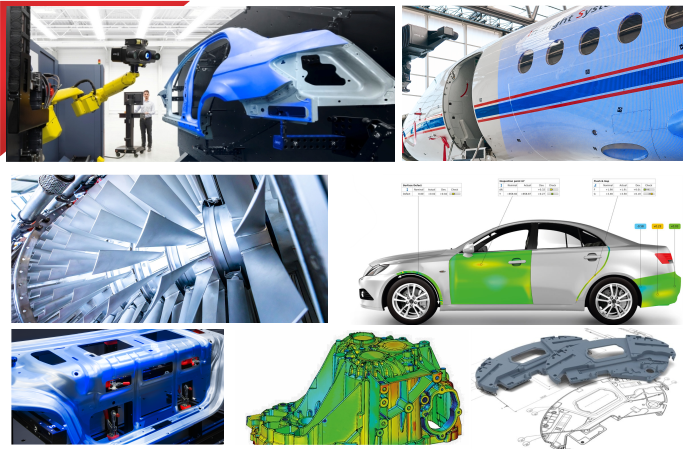

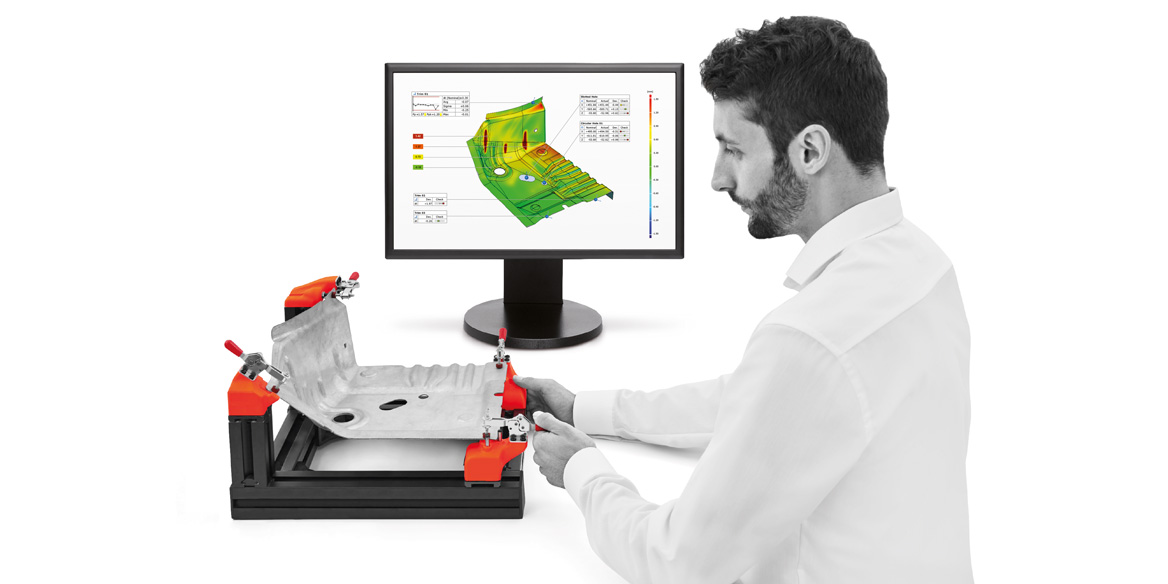

Measuring systems from GOM are used in stamping, bending, drawing, pressing, and forming process chains to guarantee consistent quality assurance: from determining the sheet metal properties, via accelerating tool try-out and first article inspection, up to series accompanying production control and assembly analysis.

Quality control in sheet metal forming processes

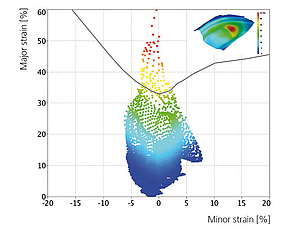

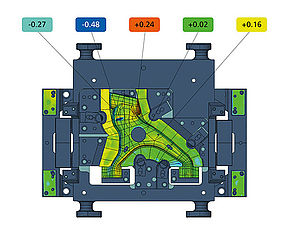

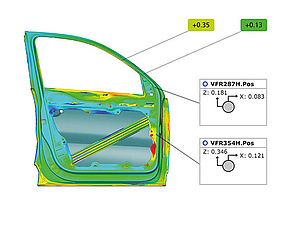

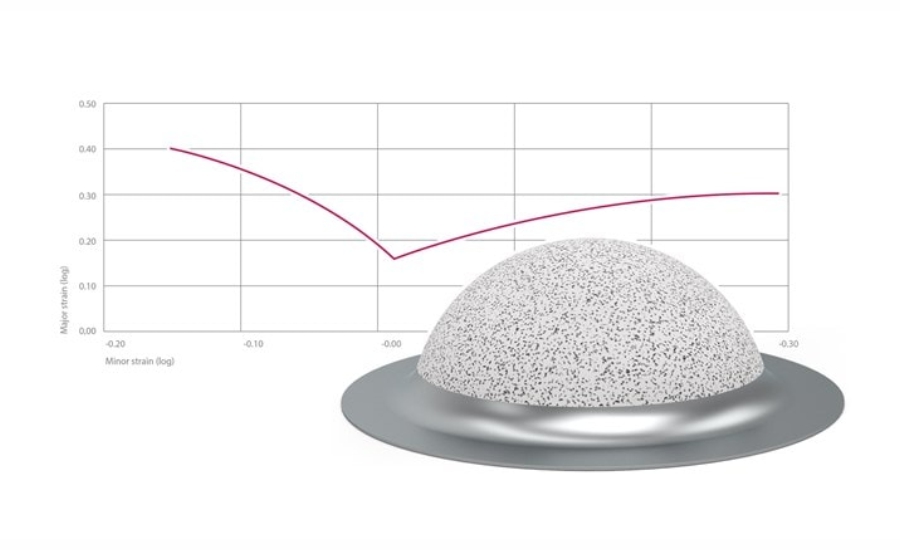

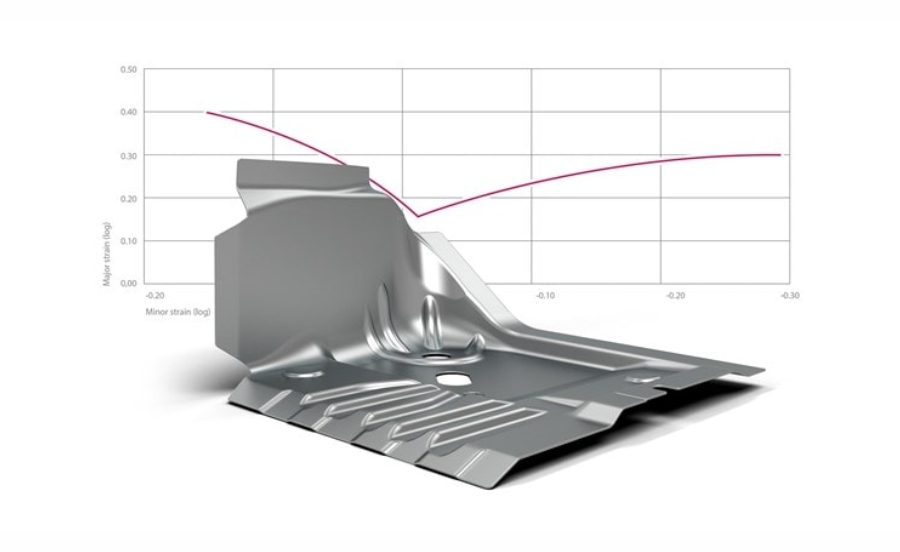

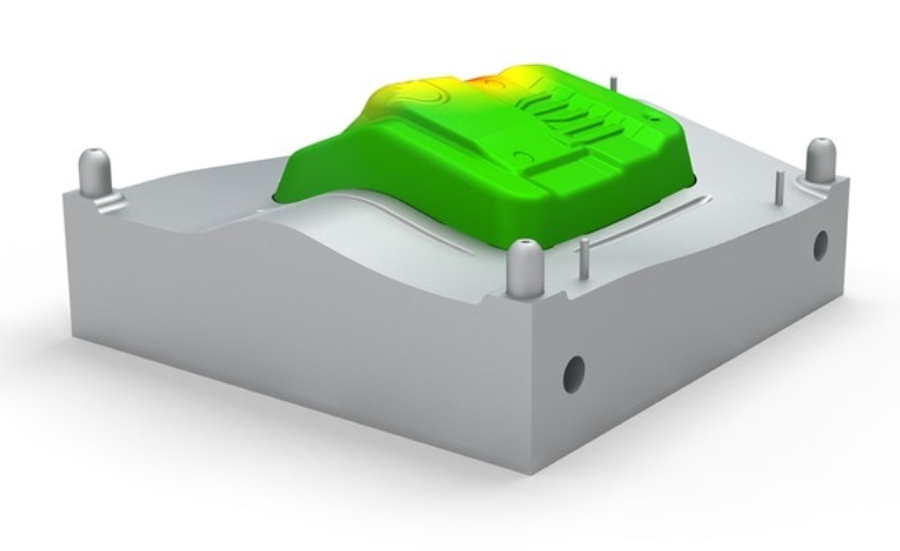

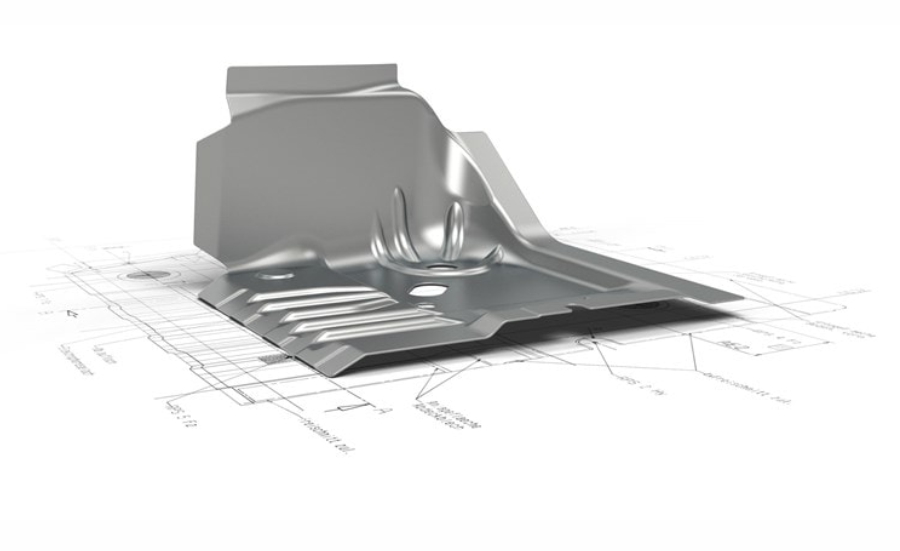

For design and simulation, GOM systems provide precise material properties by determining the forming limit curve (FLC). During try-out, sheet metal parts are checked for shape and dimensional accuracy as well as for material defects: part geometry, springback, trimming, hole patterns, material thickness, and forming limit analysis. For the series-accompanying quality control, all measurement and inspection processes are automated.

Design and Simulation

Tool Making

Sheet Metal Parts

Metal forming processes

Material Properties

Design

Simulation

Tool Making

First Article Inspection

© 2022. APM Technologies 3D Pvt Ltd

Copyright © 2022. All rights reserved