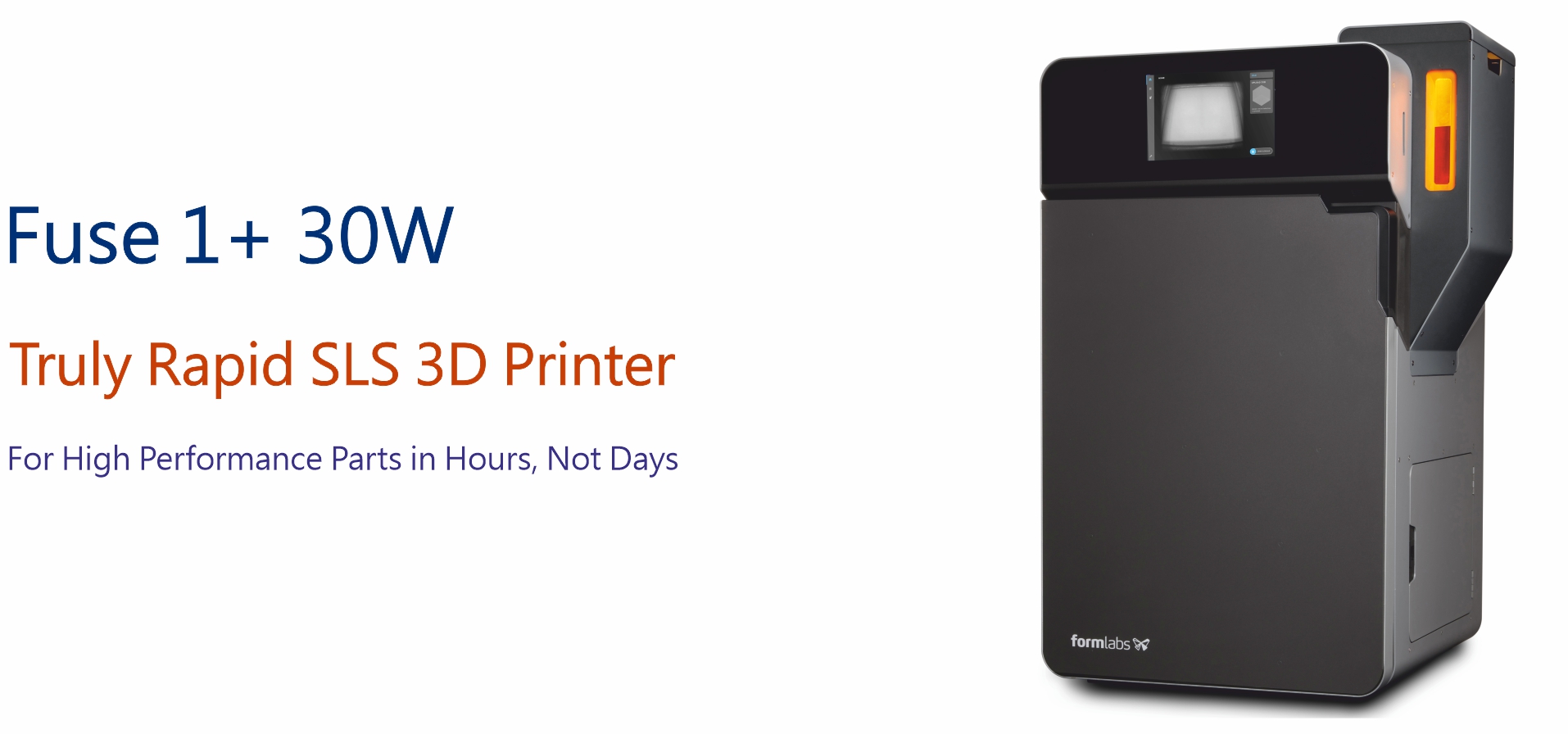

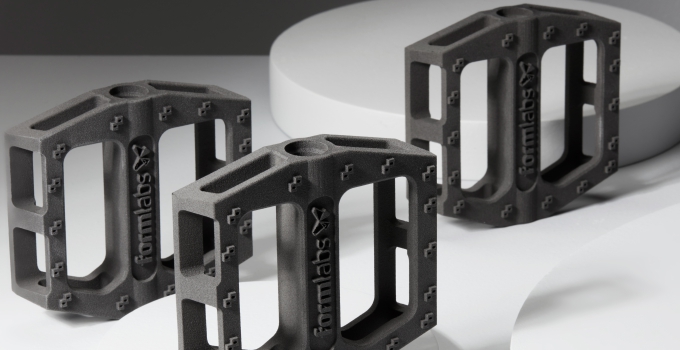

Fuse 1+ 30W

© 2023. APM Technologies 3D Pvt Ltd

Copyright © 2023. All rights reserved