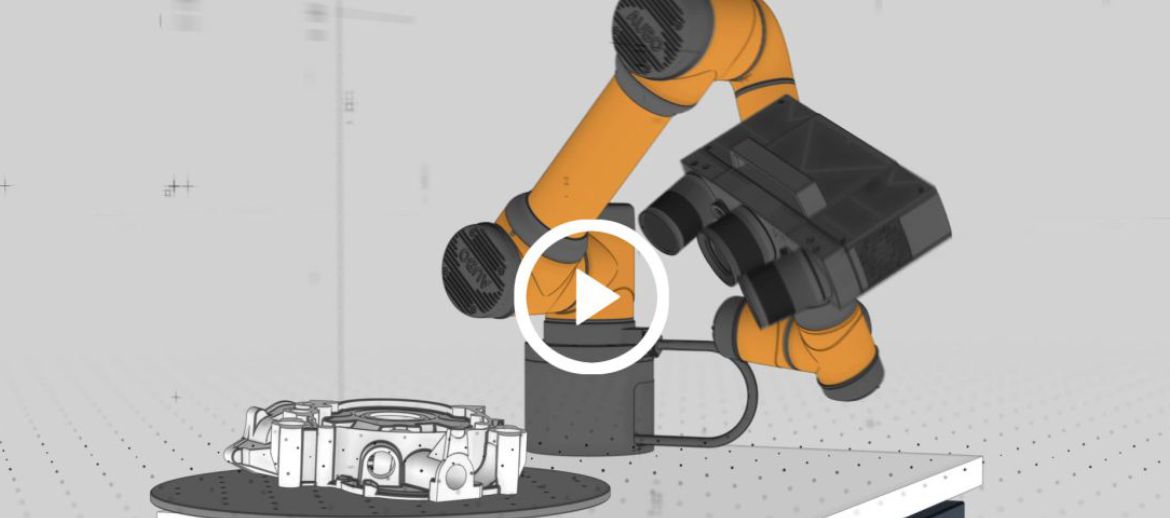

User-friendly entry-level solution

The Automation department at GOM is headed by Dr. Carsten Reich. During the interview, he characterizes the GOM ScanCobot as an easy-to-use entry-level solution for automated optical 3D metrology, giving the metrologist more time for data evaluation and problem analysis.